85 ถนนกาญจนาภิเษก แขวงบางบอนเหนือ เขตบางบอน กรุงเทพฯ 10150

Tel : +(66)2-899-6374 , +(66)86-308-0698

Fax : +(66)2-899-6371

E-mail : info@pcb-bangkok.com

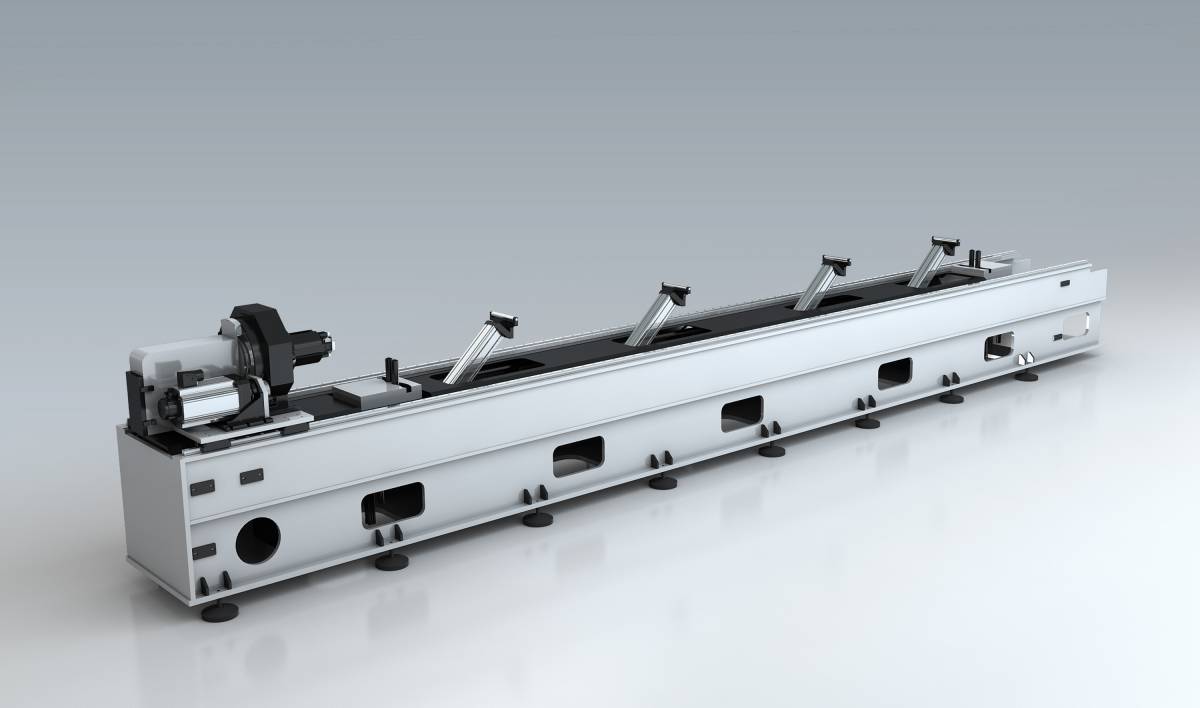

High-end intelligent CNC Laser Pipe Cutting Machine, especially for metal tube and pipe cutting. With Auto bundle loading system for automatic continous production.

Model number : i25A i35A (P2560A)

Especially for metal tubes and pipes with high precise cutting... Suit for different shape metal tube and metal pipes laser cut, such as cutting round pipe, square pipe, rectangular pipe, triangle pipe, oval pipe, and other shaped tubes and pipe.

The Tube Outer Diameter Can Be 20-250mm (20-350mm), Tube Length 6m. With Auto bundle loading system for automatic continuous pipe laser cut.

Automatic edge patrol, automatic centering, weld recognition, and automatic slag removal are all available

Fully support the expansion of customers' personalized needs

Ensure the steady of high-speed cutting for the long and heavy pipe cutting by laser. It is basic of the machine quality. Golden Laser Pipe laser cutting Machine body use more than 22mm thick iron plate welding,

Through 600-degree high-temperature annealing and natural cooling treatment, the stress of the equipment is removed, and the bed will not deform for 20 years.

|

German PA Bus Controller System for Laser Pipe Cutting Machine... The laser pipe cutting system uses a brand-new UI interface. After the system is upgraded, it includes 7 modules: planning, production, process, debugging, maintenance, diagnosis, and setting. The entire system is more intelligent and digital and can be seamlessly connected with the MESS intelligent cloud data management system of the intelligent manufacturing factory. It is a real pipe laser cutting machine CNC controller system, good performance in fiber laser tube cutting machine, support G-code transmission, realize the processing file can be used in other CNC processing machine. Connecting with other metal working machines is possible. |

|

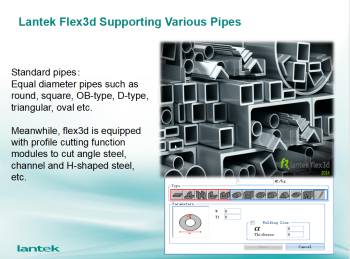

Spain Lanteck CAM Software ... Especially for metal tube and pipe cutting design and nesting, suit for different shape tube and pipe cutting, such as round, square, rectangular, triangle, oval, waist tube and other open shaped tubes and pipe, as I beam, Channel beam (for option). |

|

|

Golden Laser UI Touch Screen... A large touch screen with UI design give excellent user experience to the operator. Visualization operates easy to understanding and avoid misoperation in the laser tube cutting. |

|

Full Gear & Rack Transmission System ... All the tube laser cutting machines update to the fully Gear and Rack design, increase 20% speed and 200% accuracy than old structure design. Ensure more excellent laser cutting results on the tube. Meet more high accuracy processing demand.. |

|

|

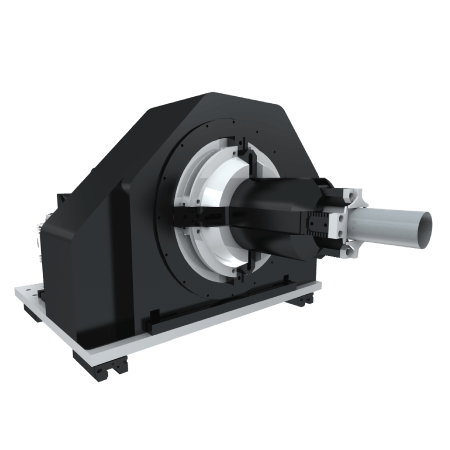

New Generation Main Chuck ... The main chuck innovatively uses a casting frame for embedded installation, which is integrated with the main body of the machine tool, and the ultra-high-speed cutting is as stable. There is no need to adjust the jaw position for full-stroke clamping. |

|

New Generation Tailer Chuck ... Unique pneumatic chuck design is one of the most important parts in the tube laser cutting machine, through many year updates, accumulated lots of experience on structure design. Selfcenter easy to hold different shape tubes, different diameter, and thickness, Adjustable clamping force... |

|

|

Floating Support The Tailer Tubes ... Servo motor floating supporter design gives better support according to the pipe shape and length. No matter the short or long tailer tube both have good support. Avoid the tailer tube too heavy to hard to download and distortion during rotary... |

|

|

Automatic Finished Tube Receiving Device ... It can be equipped with a crawler receiving device to realize automatic sorting and storage of workpieces, saving labor energy. |

|

|

| Pipes diameter greater than 100 mm, the wastage is 180-200 mm. After clamping the pipe, the overall size of the jaws opening exceeds the center hole of the chuck and cannot be passed through. The jaws will move to the closest position to the laser head for cutting... Pipes diameter of less than 100 mm, the wastage is 50-80 mm. When cutting to the last tail part, the front chuck jaws automatically open, and the rear chuck jaws can pass through the front chuck and move to the closest distance to the laser head for cutting... |

Pipes diameter greater than 100 mm, the wastage is 180-200 mm. After clamping the pipe, the overall size of the jaws opening exceeds the center hole of the chuck and cannot be passed through. The jaws will move to the closest position to the laser head for cutting... Pipes diameter of less than 100 mm, the wastage is 50-80 mm. When cutting to the last tail part, the front chuck jaws automatically open, and the rear chuck jaws can pass through the front chuck and move to the closest distance to the laser head for cutting... |

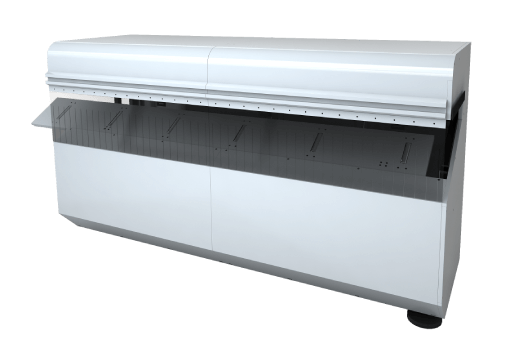

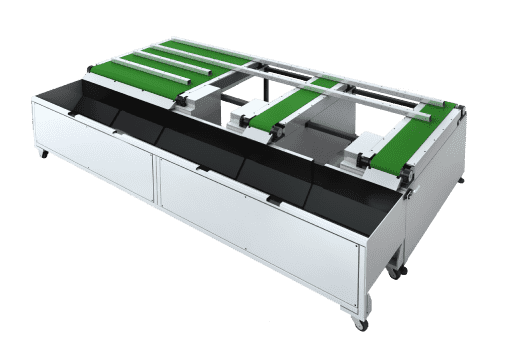

The Auto Bundle Loading System for Laser Pipe Cutting Machine.

The automatic loading system realizes the automatic continuous production, is especially for mass production demand. Improve production efficiency. ..

Tubes auto feeding system suit for 800*800mm bundle pipe loading. With automatic measure function to ensure loading the right pipe without any mistake. The alarm warning system reminds the operator during the whole production, PLC controller of the automatic loading system easy to adjust according to the detail processing demand, Autoloading, Your best choice for mass tube laser cutting...

Laser Pipe Cutting Machine Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, galvanized steel, alloy steel and so on.

Laser Pipe Cutting Machine Applicable Types of Tubes

Round tube, Squre tube, Rectangle tube, I beam, Channel beam, Angle iron and so on

Laser Pipe Cutting Machine Application Industry

Mainly used in fitness equipment, office furniture, shelves, steel structure, medical industry, rail rack and other industries for round pipe, square tube, rectangular

High-end intelligent CNC laser pipe cutting machine P Series Tube Laser Cutter Technical Parameters