85 ถนนกาญจนาภิเษก แขวงบางบอนเหนือ เขตบางบอน กรุงเทพฯ 10150

Tel : +(66)2-899-6374 , +(66)86-308-0698

Fax : +(66)2-899-6371

E-mail : info@pcb-bangkok.com

Function overview

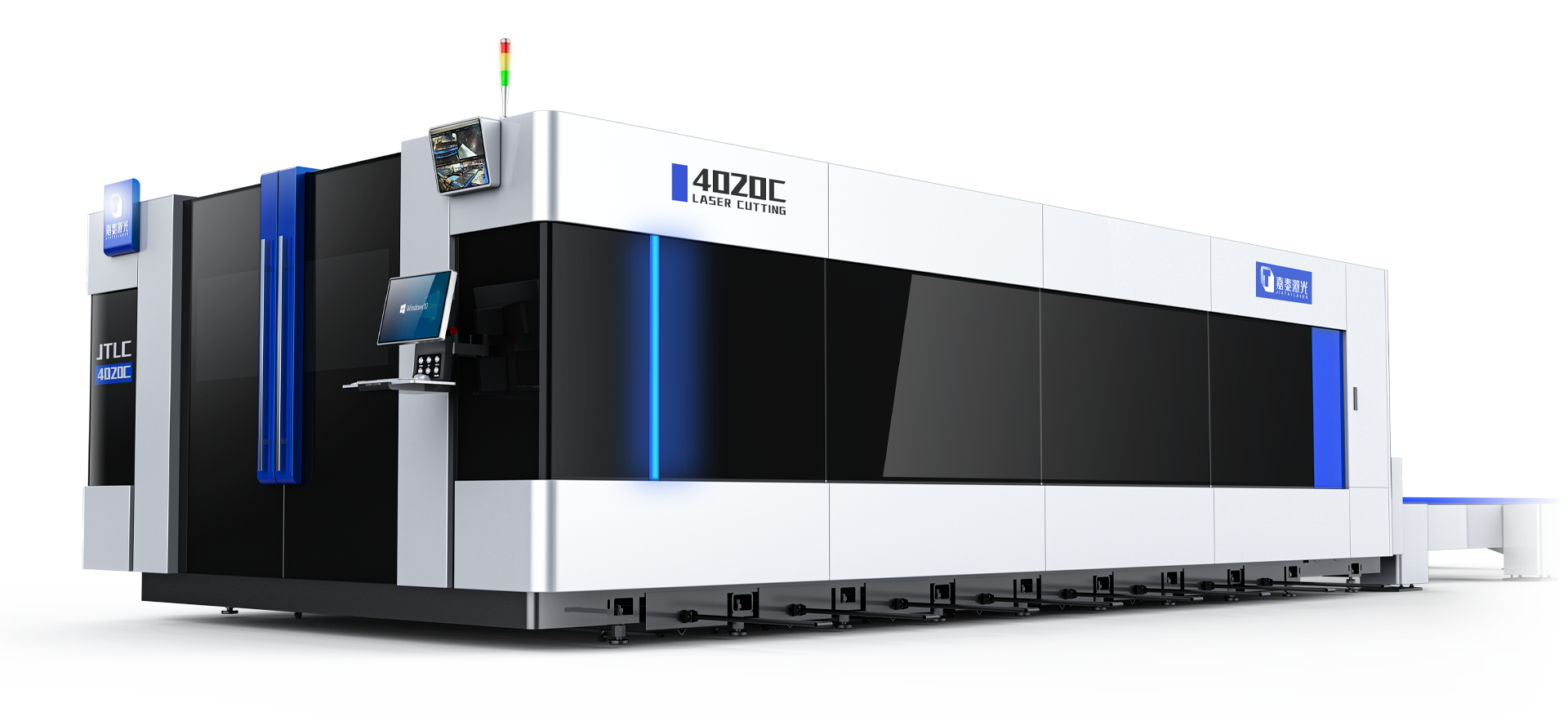

LC series cutting machine is a cutting equipment with high dynamic performance, high speed, high speed, high precision, high quality, super stability, and equipped with high intelligence system and extremely low operating cost. The equipment has many domestic leading excellent functions, greatly improves the efficiency of our production, simplifies the operation process, and is a cutting equipment with high cost performance

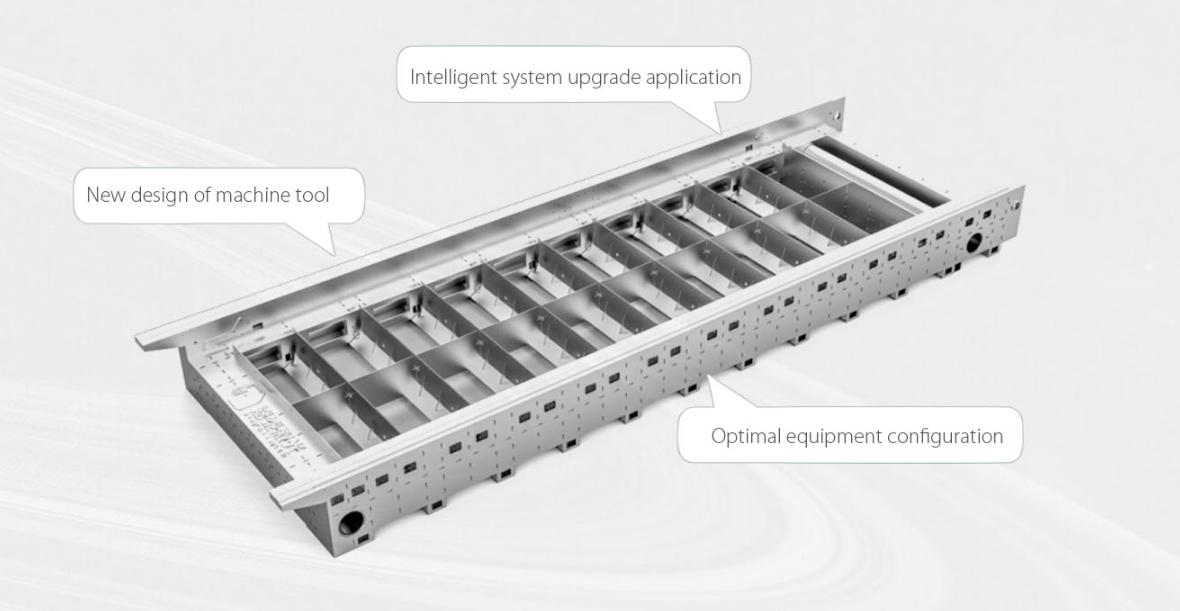

Integral welded box type

Integral welded box structure

The thickness of the internal cross rib plate is 12mm, the thickness of the external wall plate is 18mm, and the plug welding technology is used, so the structural strength is higher Ensure the stability and practicability of the equipment

Safety and environmental protection 0 pollution

All the details of the fully enclose sed structure, the exclusive optical fiber w wavelength visible protection window, standard dust removal system and so on are all for you to have a safe and pollution free production environment

The large enclosure and full protection structure, exclusive laser protection window, powerful smoke and dust removal system and intelligent bus system give you an intelligent and safe working environment.

• Big encirdement and full protection

• Strong smoke and dust removal

• bus system

• Active obstacle avoidance

• Visual residual cutting

• Process monitoring

The crossbeam is made of lightweight casting structure, rough machining after annealing to eliminate internal stress and finish machining after secondary vibration aging treatment. The stress caused by casting and processing is better solved, and the stability of crossbeam is improved.

Product Features

• Gantry-type single sided dual-drive structure, imported high-precision reducer, gear, rack and linear guide, smooth transmission, fast acceleration, high positioning accuracy;

• By adopting autornatic zoom cutting head, the positions can be set by the systern parameter to change the position of focal point of the cutting, without conventional manual adjustrment.

• Featured with lens monitoring, which can automnatically identify if the temperature of lens is normal to ensure the stabilty of product processing.

• The powerful technological functions such as one key calibration, automnatic edge searching, autornatic layout, leapfrog and so on make operation easy and simple.

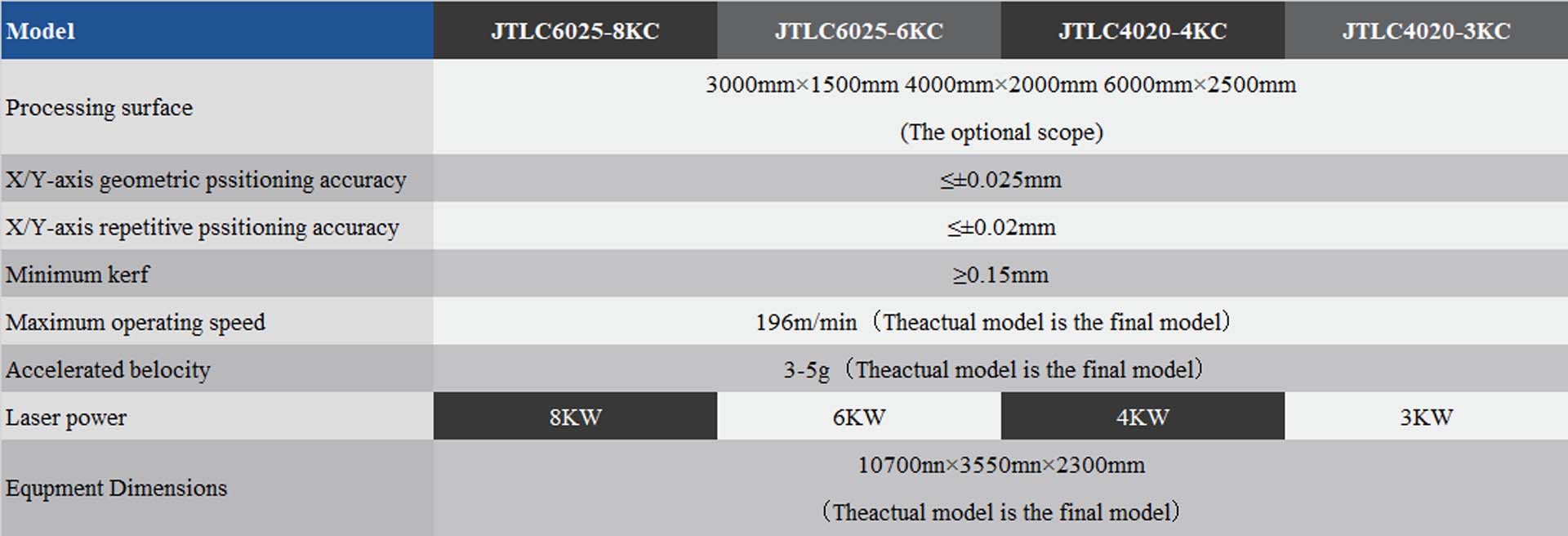

Product parameter