85 ถนนกาญจนาภิเษก แขวงบางบอนเหนือ เขตบางบอน กรุงเทพฯ 10150

Tel : +(66)2-899-6374 , +(66)86-308-0698

Fax : +(66)2-899-6371

E-mail : info@pcb-bangkok.com

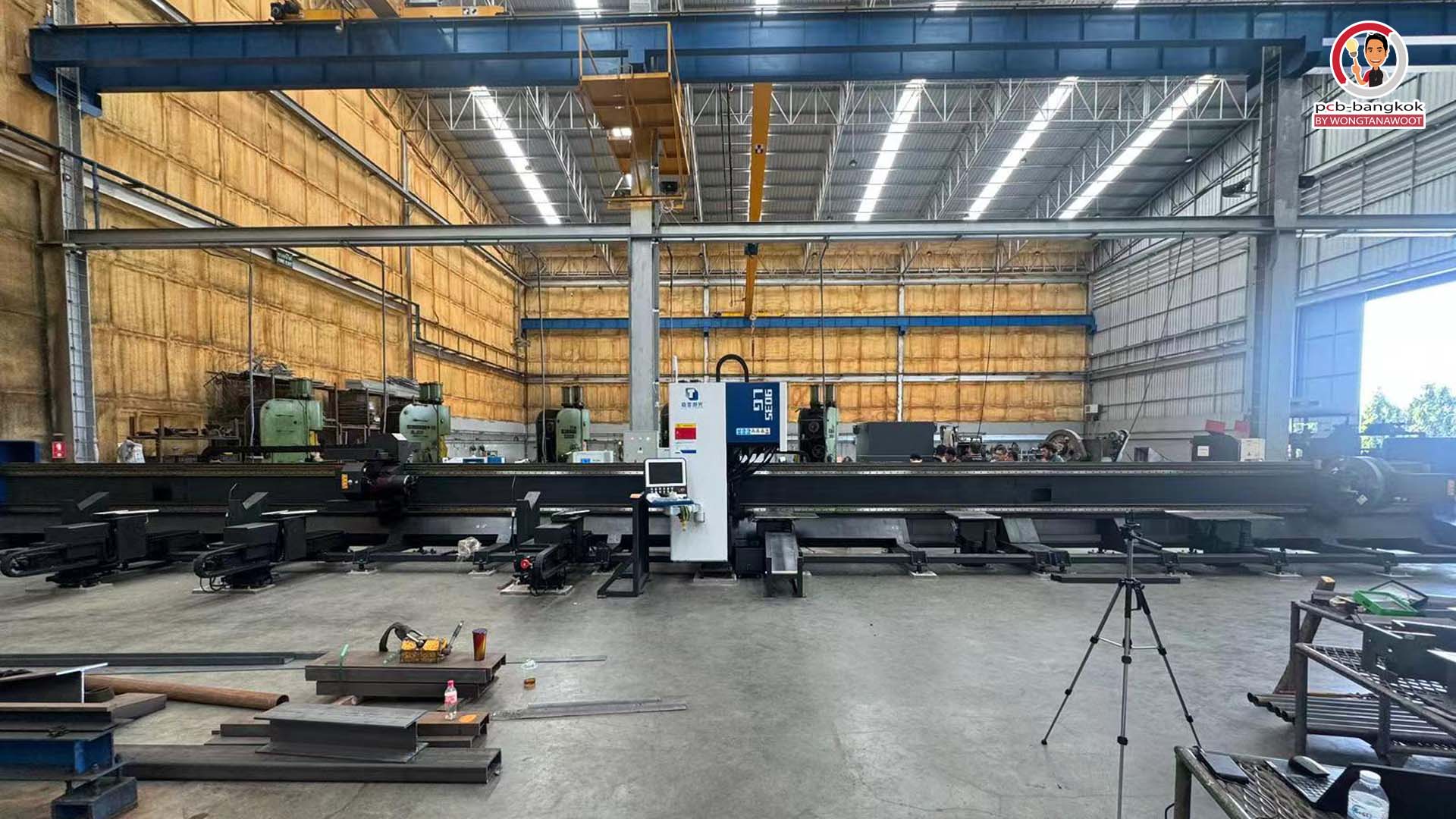

Profile of fiber laser pipe cutting machine

|

|

Laser pipe cutting is the best method of pipe cutting among various pipe cutting technologies available today. The advantages of laser pipe cutting are: small thermal deformation, high cutting accuracy, low noise, no pollution, easy to achieve automatic cutting, although the initial investment is large (disadvantage), but the processing cost is 50% less than mechanical processing. As an advanced manufacturing technology, laser cutting has the advantages of wide range of applications, flexible processing, high processing accuracy, good quality, clean production processing and easy to achieve automation, flexibility, intelligence and improve product quality, labor productivity, etc.

Fiber laser is a hot spot in the field of laser in recent years. In the processing field, fiber laser has a rapid trend to replace of traditional YAG, C02 laser. It is widely believed that the medium power fiber laser will be the third generation of the most advanced industrial processing laser. Fiber laser has many unique advantages: good beam quality; small size, light weight, maintenance-free; simple and easy to operate air cooling; low operating cost, can be used in industrial environment; long life, high processing accuracy, high speed; high efficiency of electrical energy conversion, can achieve intelligence, automation, flexible operation, etc. From the whole development of laser technology, fiber laser represents the direction and trend of laser development, and it has important application prospect in industry and national defense.

JTLG9035-6000 with 3 chucks is the latest special CNC fiber laser pipe cutting machine with international level developed by Zhejiang Jiatai Laser Science and Technology Co., Ltd.

Functional characteristics of each part

1. Fiber laser source

JTLG9035-6000 with 3 chucks series fiber laser cutting machine adopts new advanced fiber laser for industrial application. Fiber laser is the latest generation laser, representing the trend of laser development, widely used in processing of various plates and nonferrous metals.

Unique advantages of fiber laser:

1. Electro-optical conversion efficiency ≥ 40%.

2. Extremely excellent pulse power/energy stability.

3. Long life, high precision, pump sources life > 100,000hours

4. Faster speed and more perfect result.

5. Beam quality optimization for application;

6. Compact structure design.

7. Low cost compact solution, with semiconductor fiber as laser generation medium, no laser generation gas, green and environmental protection.

8. Small size, light weight, maintenance-free.

Laser technical specifications:

| Optical parameter | Unit | RFL-C6000S |

| Operation mode | Continuous/modulated CW | |

| Center wave length | nm | 1080±5 |

| Standard output power | W | 6000 |

| Output power stability | % | <±1.5 |

| Maximum modulation frequency | Hz | 1-5000 |

| Output fiber core diameter | μm | 100/50 |

| Power adjustment range | % | 10-100 |

| Output fiber length | NA | 0.2 |

| BPP | mm.mrad | 2.7-3.1 |

| wall-plug efficiency | % | ≥40% |

| Input power supply | VAC | 3-phase, 50/60Hz, 380±15% |

| Dimensions(W*D*H) | Mm | 455*802*168 |

| Weight | kg | 70 |

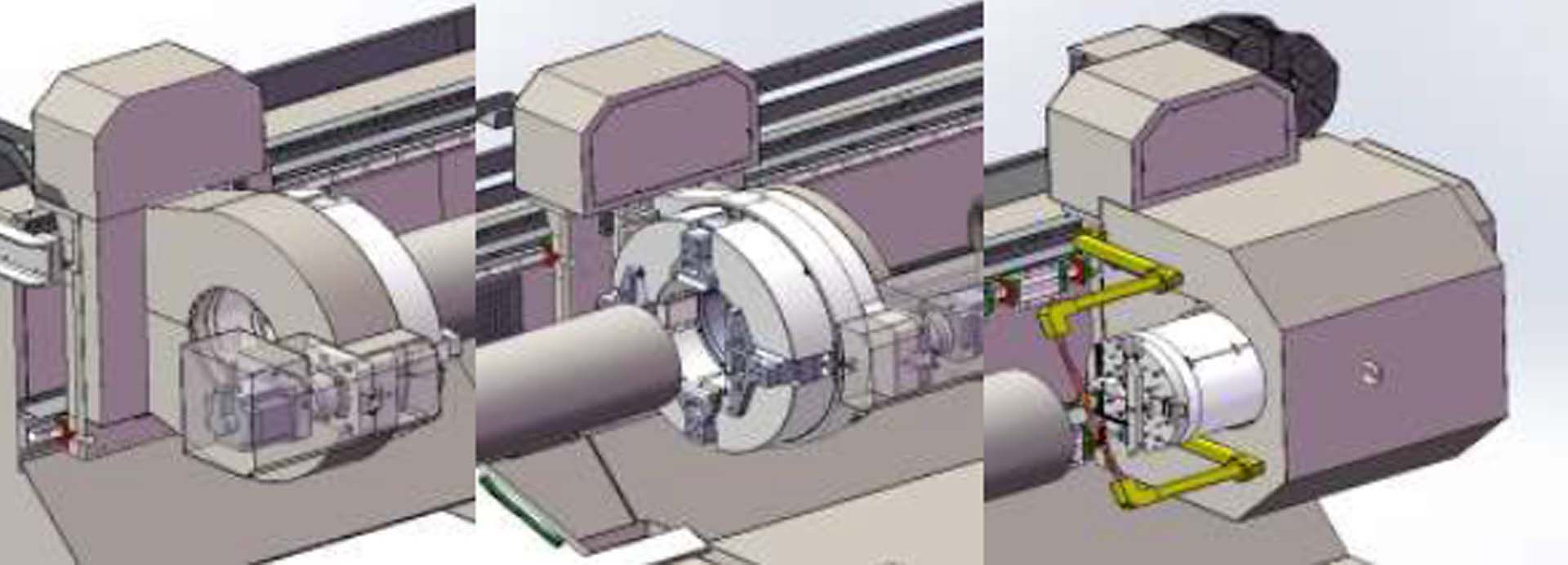

2. Structural features of three chucks :

As shown in the figure, the 9035T-6000 is a three group chuck structure that can provide multiple cutting states and clamping effects through different combinations of three groups of chucks. Compared to the traditional double chuck structure, it has the following advantages:

1) High cutting accuracy: Three chuck structure design, adopts three chucks to clamp and support, the clamping force is adjustable to correct the loaded material which is been bent or twisted to cut properly, to avoid the cutting error caused by the displacement at the middle chuck, the machine serves two clamping modes by switching to two or three chucks to hold the material properly to efface the centrifugal force from the end side rotating.

2) Less remaining material: less remaining material means can cut the full length without material remains to reduce material wasting, increase the profit. and it supports multi-orbit mode to meet the none remaining material and other several ways as well.

3. Main machine of fiber laser pipe cutting

The main machine consists of body, beam, Z-axis device, front and rear chuck, feeding part, receiving part, operation and control part, gas and water circuit, etc.

1. Machine body: the body adopts wall plate welding structure, rough machining after annealing to eliminate internal stress, and refined after secondary vibration aging treatment, which solves the stress caused by welding and machining, thus greatly improved the stability of machine, X, Y, Z, W1, W2 axis adopt servo motor from Japan, equipped with high rigidity precision reducer and high precision gear and rack, high precision linear guide and other efficient transmission mechanism, which effectively ensures the transmission accuracy. The machine is equipped with automatic lubrication device, and the cutting area is equipped with dust and smoke removal device, and the bottom of the cutting area is equipped with scrap trolley, which can be pulled out regularly to clean up the scrap.

2. Machine beam: the beam is made of profile welded structure, rough machined after annealing to eliminate internal stress, and refined after secondary vibration aging treatment, which solves the stress caused by welding and processing, thus greatly improving the stability of machine.

| 3. Z-axis up and down device: the Z-axis up and down device is to realize the up and down movement of cutting head, the capacitive sensor in Z-axis device detects the distance between cutting nozzle and the surface of pipe, and feeds the signal to control system, then the control system controls Z-axis motor to drive the cutting head up and down, thus controlling the constant distance between cutting nozzle and plate and effectively ensuring the cutting quality. |  |

4. The part of chucks: Adopt advanced pneumatic chuck, the chuck aperture is 360mm which can process the parts with external circle diameter 30mm to 350mm. Adopt high-speed lightweight chuck and equipped with high-precision servo motor, through six-stage precision gear transmission, it can achieve synchronous rotation of three chucks, to ensure better accuracy of cutting.

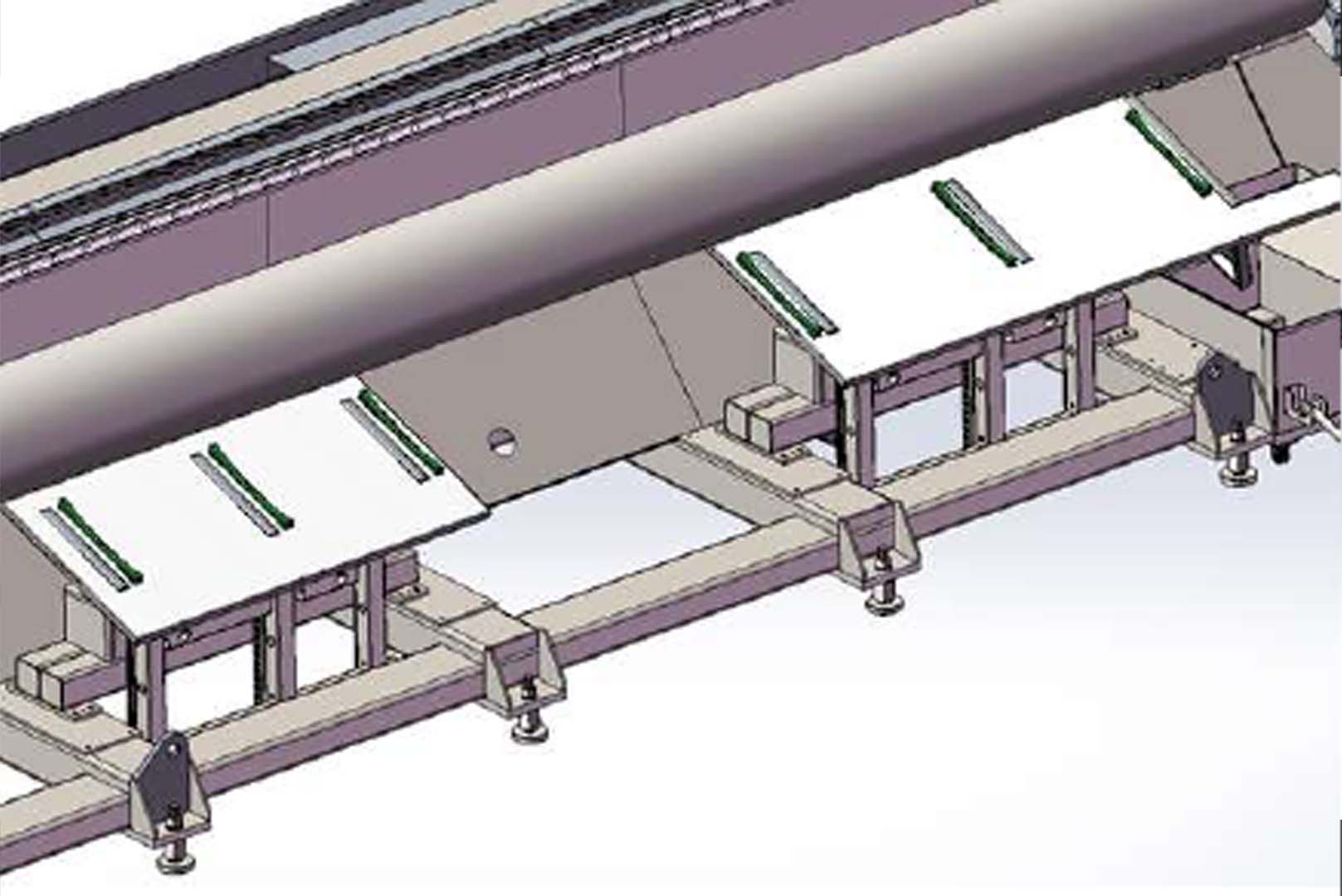

5. Loading and feeding parts: The moving plate adopts light weight welding structure, machining roughly after annealing to eliminate internal stress, and finishing after secondary vibration aging treatment, which solves the stress basically caused by welding and machining, thus greatly reducing the weight and improving the strength and rigidity to ensure efficient feeding. The unique auxiliary feeding mechanism for large pipes greatly shorten the feeding time of large pipes and improves the operation efficiency of whole machine, and this technology has obtained the national patent.

6. Receiving part: the receiving part adopts multiple groups of supporting axis and flipping, the supporting device always follows the change of pipe rotation radius to ensure effective supporting and prevent pipe sagging, which improves the processing accuracy.

7. Gas and water circuit system: Fiber laser cutting machine gas circuit has two parts, one is the cutting gas supplied to cutting head, you can use clean and dry compressed air, high purity oxygen and high purity nitrogen. The other part is the auxiliary gas for machine movement, all of which is clean and dry compressed air. The cutting gas is divided into three types: nitrogen, oxygen and air, and these three can be freely selected by hand. The auxiliary gas in working table drive the cylinders directly, making full use of the efficient capacity of dust removal fan to remove smoke and dust. The water circuit system mainly consists of two parts: one is the cooling water coming out from the chiller, one way gets into the laser source, circulate in cold air condition and back to the chiller. One way gets into the laser cutting head part. circulate and back to the chiller.

Cutting head and follower

The cutting head adopts a non-contact height automatic tracking system dedicated to Jiatai laser fiber laser cutting head and capacitance. According to the physical characteristics of optical fiber lasers, the standard 5-inch focal length lens of the cutting head can be used for cutting plates of different thicknesses, avoiding the trouble of replacing different focus lenses. Suitable lenses can also be replaced according to customer plate requirements.

|

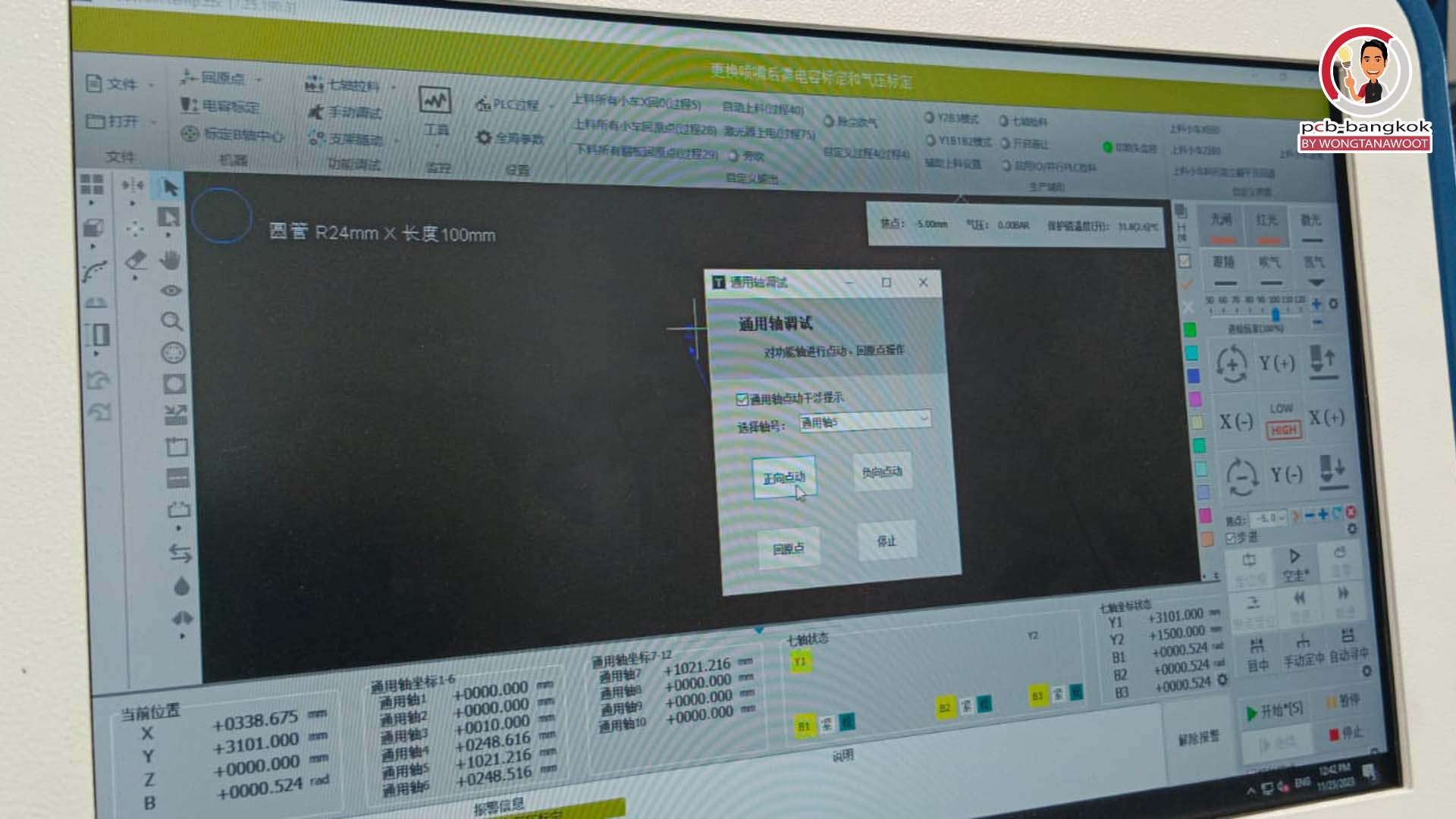

CNC system JTLG9035-6000 fiber laser pipe cutting machine adopts the CypTube numerical control system, which represents the most professional laser processing numerical control system. Compact and modular in structure, with its good cost performance ratio, meet the needs of users to use high-performance CNC systems. |

|

|

Reasonable architecture: Advanced system design architecture, with all system software running on the main PC processor, rather than the traditional dual CPU design philosophy. |

|

| Leading technology: CNC technology application based on PC platform, with more than 20 years of experience. All functions are open to users in a modular form without any hardware changes. |  |

Superior performance: Complete five-axis linkage and coordinate transformation functions, capable of complex multi-axis and multi-channel coordinated control, meeting the application requirements of various CNC equipment. It can quickly and automatically correct and process pipes with slight distortion and deformation.

Perfect functionality: Provide a wealth of functional options, optimize configuration for application areas, and achieve the most perfect performance/price uniformity.

Friendly interface: The dedicated CNC real-time kernel overcomes the real-time control challenges on the Windows operating system platform. On the basis of ensuring the excellent real-time performance of the CNC system, it highlights the characteristics of easy operation and friendly interface of the system.

Processing of special-shaped pipes: It can adapt to the application of various pipes, and can also perform typesetting and processing for special-shaped pipes that cannot be recognized by most software.

Application field and cutting ability

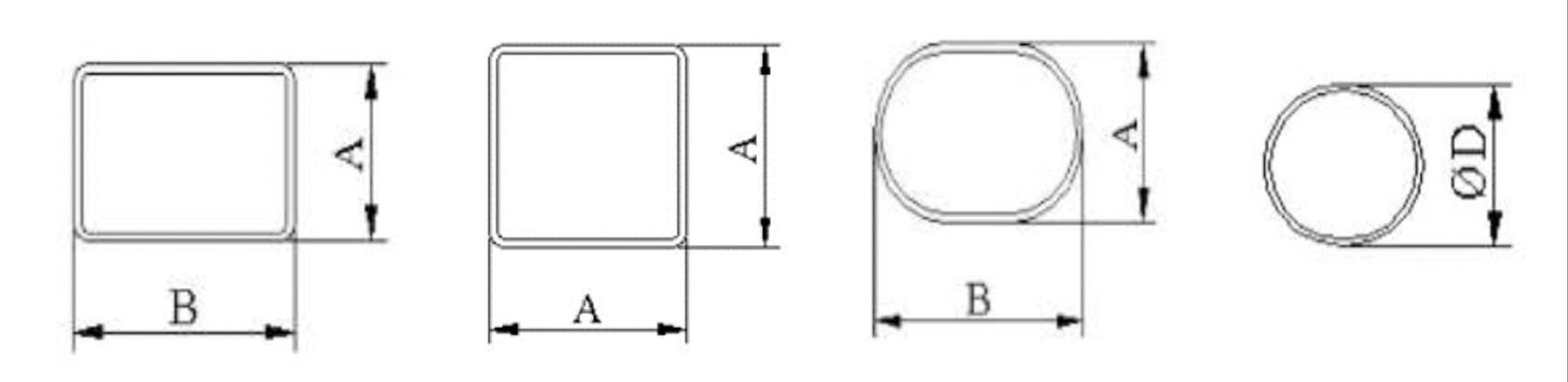

1. Suitable for cutting space: square tubes, circular tubes, elliptical tubes, and angle steel shaped pipes.

2. Application industries: various machinery manufacturing and processing industries, such as food machinery, kitchenware and bathroom, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, automobiles, decorative advertising, aerospace, shipbuilding, engineering machinery, locomotives, agricultural and forestry machinery, electrical manufacturing, petroleum machinery, fitness equipment, furniture, laser external processing services, etc;

3. Cutting materials: carbon steel, stainless steel, aluminum alloy, brass, red copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy;

4. Relevant technical requirements for pipes

4.1 The processed pipes shall be not seriously corroded, which may affect the quality of cutting section;

4.2 The twisting and bending of pipes shall not be lower than the <GB/T 6728-2002 Structural Cold Forming Hollow Steel- Dimension, Shape, Weight, and Allowable Deviation>;

4.3 The pipe shall be flat and straight, with curvature of 1mm/1m (4mm/6m);

4.4 The tolerance of pipe shall not be greater than outer diameter± 0.5%, with minimum of 0.2mm (according to the standardized outer diameter deviation grade D4 of GB/T 17395-1998);

4.5 The twist degree in the length direction of pipe shall be less than total length 0.02%;

4.6 Workpiece processing accuracy: based on material error, the position error is IT12 and the contour error is IT12;

4.7 The section roughness of cutting 0-6mm material is 6.3um-12.5um, which depends on different material and thickness;

4.8 The pipe ends have burrs due to fly saw cutting, and the height of burrs should be less than 3mm;

4.9 Because the height of welding seam will affect laser penetration and clamping action, the external remains of welding seam needs to be removed, and it has to be basically flat and the height of inner welding seam needs to be less than 2mm when processing welding pipes;

4.10 Adapt to the environmental requirements of workshop temperature of 5°-45℃ and relative humidity ≤ 90%

4.11 The buyer must maintain the machine regularly in accordance with seller's instructions. If the machine is damaged due to unscheduled maintenance, the seller has the right not to provide service;

4.12 The contour of processed pipe is shown in the figure below. If beyond this scope, the figure of contour needs to be confirmed by both parties through negotiation

4.13 The ratio of thickness to diameter of thin-walled pipes should not be less than 1/40 to avoid deformation of pipe clamping. If the ratio is indeed less than 1/40, additional customized clamping are required;

4.14 For pipes exceeding the above figure, both parties shall negotiate whether it’s available to cut. At the same time, it is also necessary to customize special clampings. We can provide design drawings.

Cutting parameters (for reference only)

| Thickness (mm) | Power (W) |

CS(Q235) Auxiliary gas (O2) Speed :m/min |

Power (W) |

SS(304) Auxiliary gas (N2) Speed :m/m in |

Power (W) |

Aluminum Auxiliary gas (N2) Speed :m /min |

Power (W) |

Brass Auxiliary gas (N2) Speed :m/min |

| 1 | 2000 | 10 | 6000 | 35-40 | 6000 | 35-40 | 6000 | 32-40 |

| 2 | 2200 | 6.0 | 6000 | 25-30 | 6000 | 20-25 | 6000 | 18-20 |

| 3 | 3600 | 3.6-4.0 | 6000 | 16-18 | 6000 | 14-16 | 6000 | 13-14 |

| 4 | 4000 | 3.3-3.8 | 6000 | 11-12 | 6000 | 9.0-10 | 6000 | 8.0-9.0 |

| 5 | 4000 | 3.0-3.6 | 6000 | 7.0-8.0 | 6000 | 5.0-6.0 | 6000 | 5.5 |

| 6 | 4000 | 2.7-3.2 | 6000 | 4.0-5.0 | 6000 | 3.2-4.0 | 6000 | 3.8 |

| 8 | 6000 | 2.2-2.5 | 6000 | 3.8 | 6000 | 2.0 | 6000 | 1.8 |

| 10 | 6000 | 2.0-2.3 | 6000 | 2.0 | 6000 | 1.2 | 6000 | 1.0 |

| 12 | 2200 | 0.9-1.0 | 6000 | 1.2 | 6000 | 0.7 | ||

| 6000 | 1.9-2.1 | |||||||

| 14 |

2200 | 0.8-0.9 | 6000 | 1.0 | ---- | ---- | ||

| 6000 | 1.4-1.7 | |||||||

| 16 | 2200 | 0.8-0.9 | 6000 | 0.6 | ---- | ---- | ||

| 6000 | 1.2-1.4 | |||||||

| 20 | 6000 | 0.6-0.7 | ---- | ---- | ---- | ---- |

Note: The red-labeled parameters in table are parameters for sample, which are influenced by various factors in actual processing.

Main parts configuration

| NO | Parts | Brand | Remark |

| 1 | Laser source | Raycus-6000W | |

| 2 | Control system | FSCUT 5000A | |

| 3 | Cutting head | BLT421T | |

| 4 | Servo motor and drive | INOVANCE | |

| 5 | Reducer motor | Motoreducer | FRANCE |

| 6 | Rack & pinion | YYC/APEX | TAIWAN, China |

| 7 | Linear guideway | HIWIN/TBI/CSK/AirTAC | TAIWAN, China |

| 8 | Front chuck | Beut 350H | |

| 9 | Rear chuck | Beut 350H | |

| 10 | Proportional valve | SMC | Japan |

| 11 | Solenoid valve | SMC/AirTAC | Japan/Taiwan, China |

| 12 | Chiller | Tongfei | China |

| 13 | Machine body | Jiatai | China |

| 14 | Air conditioning | Jiatai | China |

| Note: In case of direct discharge, the demander will customize the external piping according to the drawing interface size and site environment provided by the supplier. | |||

Machine details

| Processing width and area | |

| Processing area | Round pipe ø30-350mm*9200mm; Square pipe 30*30-250*250mm*9200mm |

| X-axis travel | 550mm |

| Y-axis travel | 9500mm |

| W-axis pinch diameter | Round pipe D350mm; Square pipe 250mm×250mm |

| Z-axis travel | 350mm according to diameter of pipe) |

| Accuracy | |

| X, Y axis positioning accuracy | ±0.03mm/1000mm |

| X, Y axis repeat positioning accuracy | ±0.03mm |

| Z axis positioning accuracy | ±0.03mm |

| Z axis repeat positioning accuracy | ±0.03mm |

| Speed | |

| X/Y axis max. positioning speed | 100m/min |

| X/Y axis max. acceleration | 0.5G |

| W-axis maximum speed | 90rpm |

| Power supply parameters | |

| Phases | 3 |

| Rated voltage | 380V |

| Frequency | 50HZ |

| Total power protection class | IP54 |