85 ถนนกาญจนาภิเษก แขวงบางบอนเหนือ เขตบางบอน กรุงเทพฯ 10150

Tel : +(66)2-899-6374 , +(66)86-308-0698

Fax : +(66)2-899-6371

E-mail : info@pcb-bangkok.com

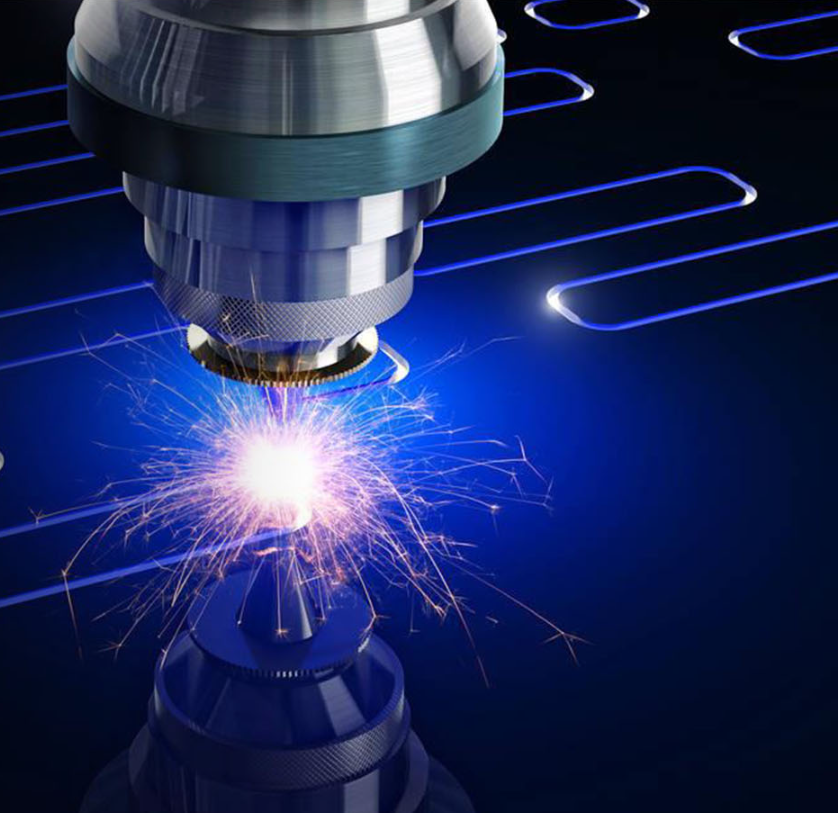

Function overview

LC series cutting machine is a cutting equipment with high dynamic performance, high speed, high speed, high precision, high quality, super stability, and equipped with high intelligence system and extremely low operating cost. The equipment has many domestic leading excellent functions, greatly improves the efficiency of our production, simplifies the operation process, and is a cutting equipment with high cost performance

Sectionalized Dedusting System

1. Cutting area is partitioned with partion plates; Real-time tracking of opening dust removal when cutting.

2. Pipes on both sides are fitted with circular tubes to reduce wind resistance

3. The suction port in each area is close to the lower end surface of the cutting platform, and the suction port is flat and long, and the flip plate structure effectively absorbs the smoke and heat

4. The trolley, cutting platform and partition partition will form a nearly confined space in the cutting area, and the smoke and heat can be well taken away through the air outlet during cutting;

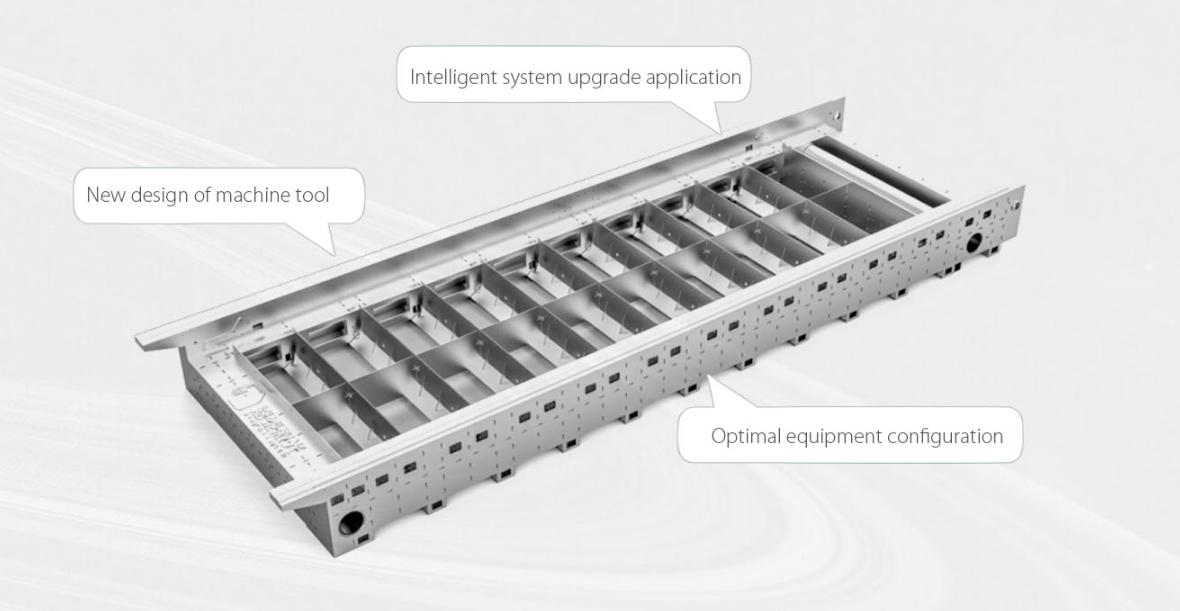

Integral welded box type

Integral welded box structure

The thickness of the internal cross rib plate is 12mm, the thickness of the external wall plate is 18mm, and the plug welding technology is used, so the structural strength is higher Ensure the stability and practicability of the equipment

Safety and environmental protection 0 pollution

All the details of the fully enclose sed structure, the exclusive optical fiber w wavelength visible protection window, standard dust removal system and so on are all for you to have a safe and pollution free production environment

The large enclosure and full protection structure, exclusive laser protection window, powerful smoke and dust removal system and intelligent bus system give you an intelligent and safe working environment.

• Big encirdement and full protection

• Strong smoke and dust removal

• bus system

• Active obstacle avoidance

• Visual residual cutting

• Process monitoring

The crossbeam is made of lightweight casting structure, rough machining after annealing to eliminate internal stress and finish machining after secondary vibration aging treatment. The stress caused by casting and processing is better solved, and the stability of crossbeam is improved.

Product parameter

Main parts configuration

| NO | Parts | Brand | Remark |

| 1 | Laser source | Raycus-20000W | CE type |

| 2 | Control system | FSCUT10000 | |

| 3 | Cutting head | BLT720 | |

| 4 | Servo motor and drive | Rexroth | GERMANY |

| 5 | Reducer motor | Alpha | GERMANY |

| 6 | Rack & pinion | Alpha | GERMANY |

| 7 | Linear guideway | THK | |

| 8 | Proportion valve | SMC | JAPAN |

| 9 | Electromagtic valve | SMC | JAPAN |

| 10 | Connector | Phoenix | GERMANY |

| 11 | Chiller | Tongfei | CHINA |

| 12 | Air conditioner For electrical cabinet | Tongfei | CHINA |

| 13 | Machine bed | JIATAI | 6025K |

| 14 | Computer | Win10 or Win11 | genuine software |

| 15 | Stabilizing Transformer | Teng teng | CHINA |

| 16 | Exhaust Blower | JIATAI | CHINA |

| 17 | Air-conditioned room for Laser source | JIATAI | CHINA |

| Note: Nitrogen high-pressure proportional valve. | |||

Machine details

| Working Area | |

| Plane Working range(L*W) | 6000mm*2500mm |

| X axis move range | 2550mm |

| Y axis move range | 6100mm |

| Mechanical accuracy | |

| X/Y Axis positioning accuracy | ±0.03mm/m |

| X/Y Axis repeat positioning accuracy | ±0.025mm/m |

| Speed | |

| X/Y Axis positioning speed | X:135m/min |

| Y:123m/min | |

| X/Y Axis acceleration | 2.0G |

| Power supply | |

| Phase | 3 |

| Rated Voltage | 380V |

| Frequency | 50Hz |

| Protection level | IP54 |